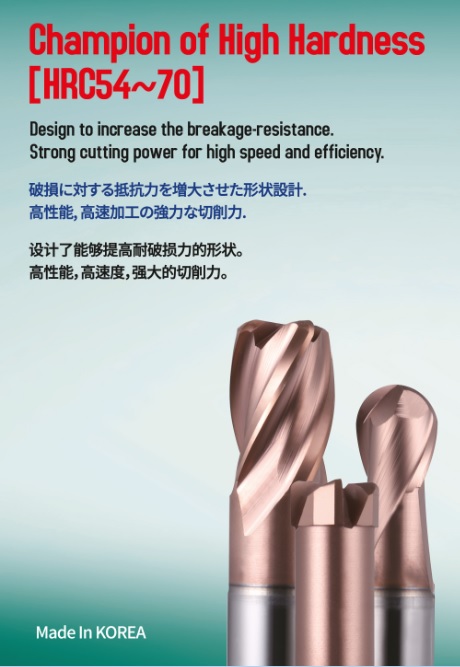

For use the End mill more economically and efficiently, select the proper End Mill by considering the shape and hardness of work mate-rial and processing efficiency.

Therefore, the diameter, number of the flute, length of the flute, helix angle and materials of the End Mill should be considered.

- Raw Material of Toll

For the cutting process from the structural steel, nonferrous materials to cast iron, Cobalt 8% HSS(SKH 59 grades) is the best. For more efficient processing and longer durability, selct the coating End Mill, power metallurgy HSS End Mill or the Carbide End Mill.

- Number of the flute

important factor of the performance of the End Mill

-2flutes : By the wider chip pocket, the chip can be discharged smoothly but the section size of the tool is narrow so its rigidity reduces. It can be used in the slotting.

-4flutes:By the narrower chip pocket, the chip cannot be discharged freely but the section size of the tool is wide to its rigidity expands. It can be used in the side cutting mainly.

- Length of the cutting part

If working by decreasing the cutting part length, the rigidity can be increased. The projection length of End Mill influences in the rigidity so avoid to increase the length unnecessarily.